Polypropylene 101

A simplified introduction to the material we know as Polypropylene.

Learn more about our new customer portal

Customer PortalThe latest research and insights on leading developments in the plastics industry. Find product explanations, properties, comparison charts and application ideas all at a glance.

A simplified introduction to the material we know as Polypropylene.

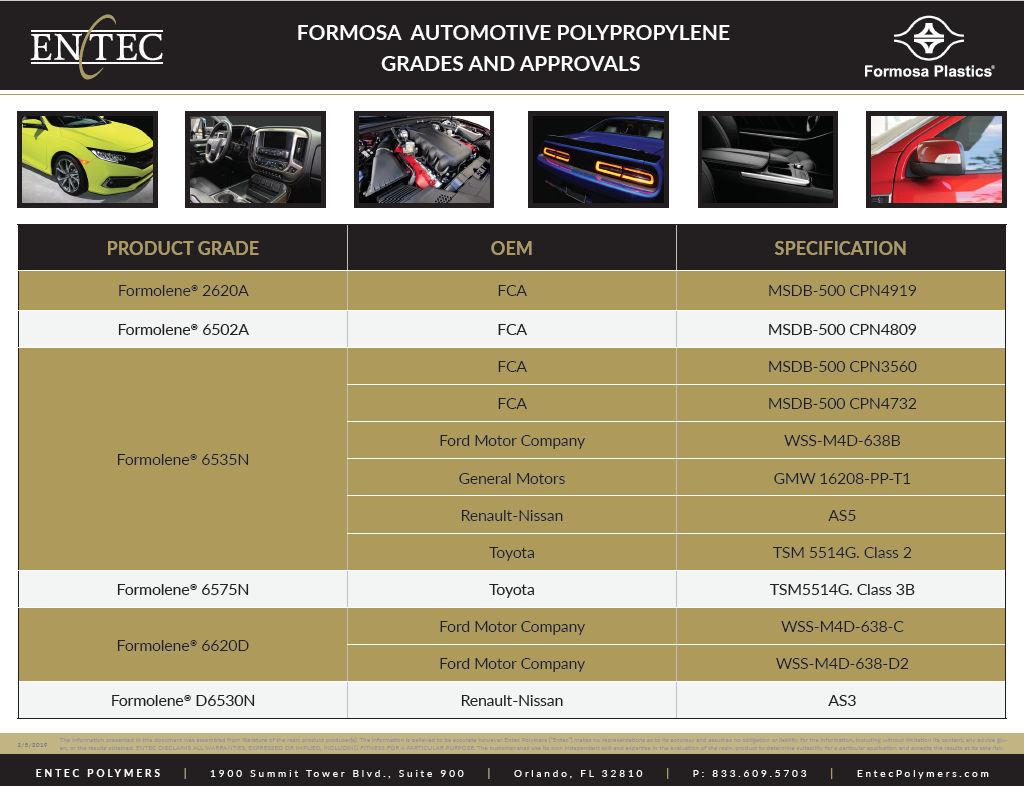

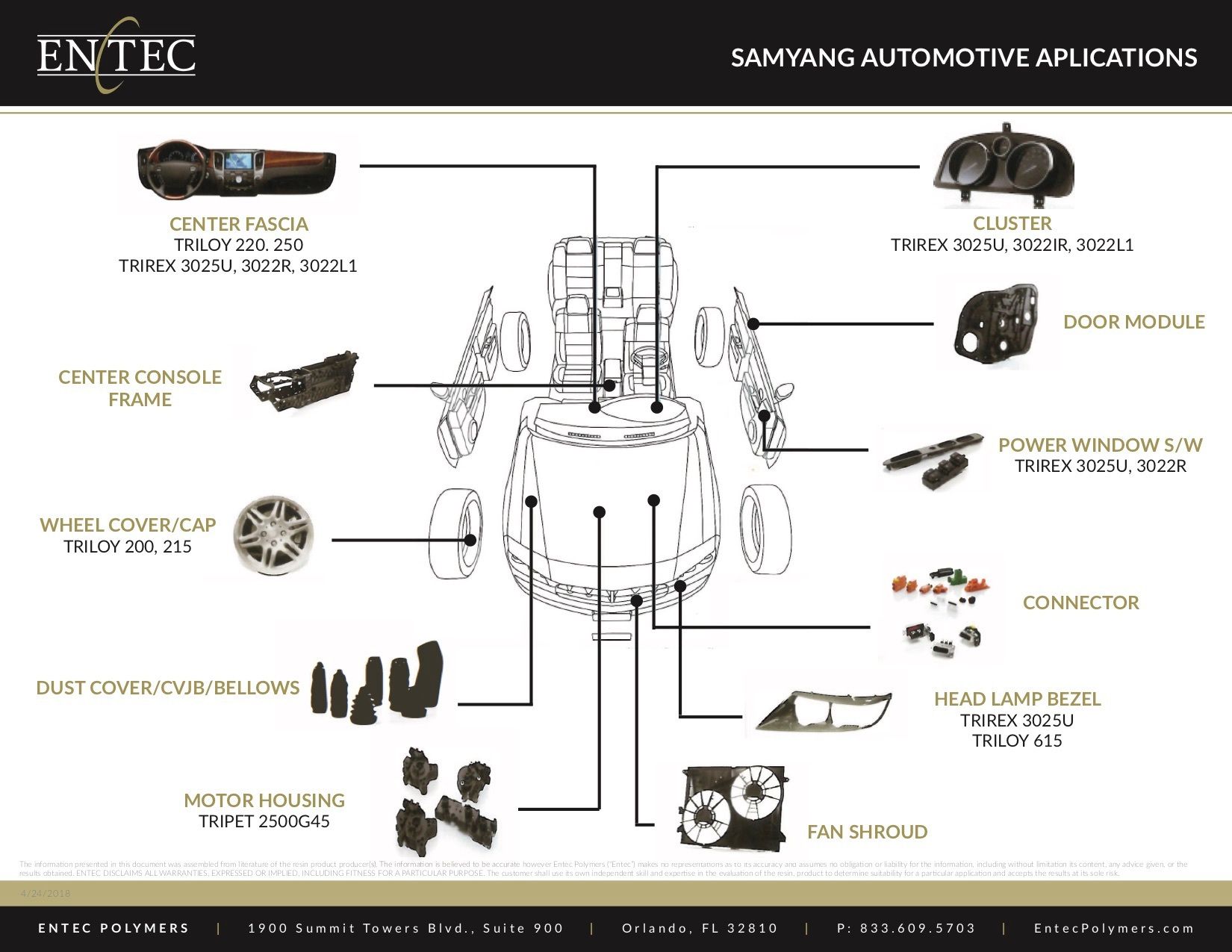

An overview of PP for automotive specifications by OEM. Please contact us for automotive approvals and applications.

A simplified introduction to the material we know as Polyethylene

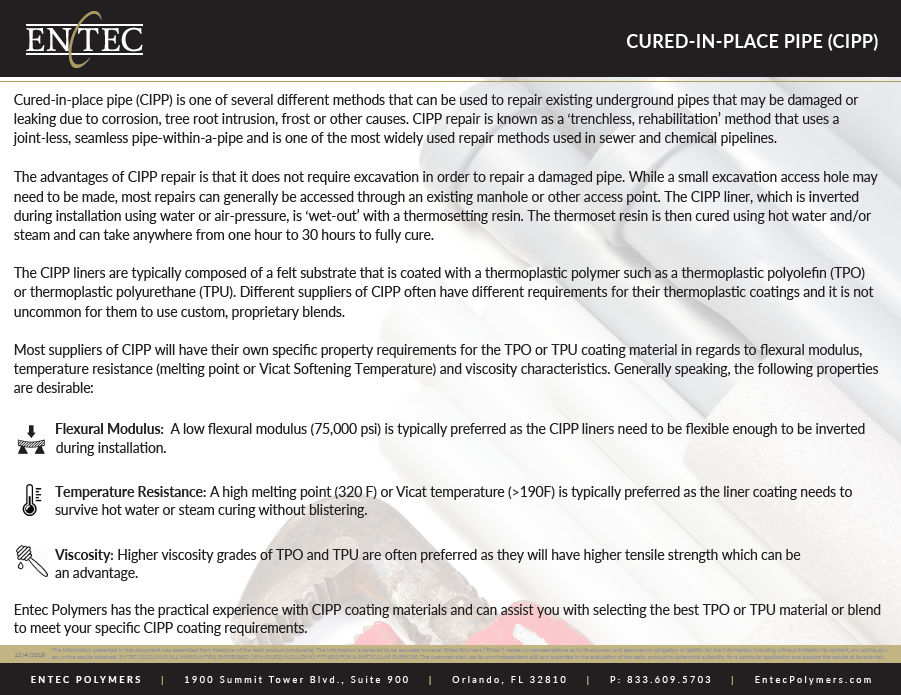

Cured-in-place pipe (CIPP) is one of several different methods that can be used to repair existing underground pipes that may be damaged or leaking due to corrosion, tree root intrusion, frost or other causes.

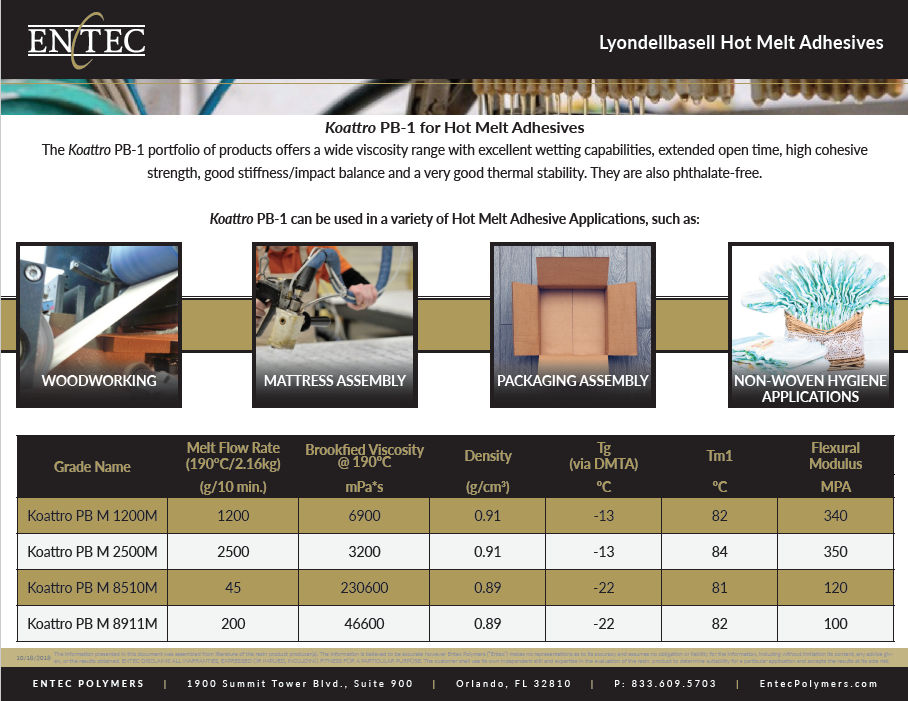

The Koattro PB-1 portfolio of products offers a wide viscosity range with excellent wetting capabilities, extended open time, high cohesive strength, good stiffness/impact balance and a very good thermal stability. They are also phthalate-free.

Pulverized resins in powder form specifically formulated for rotational molding. Use this guide to see an overview of densities and melt flows. Contact us for technical support on specific applications.

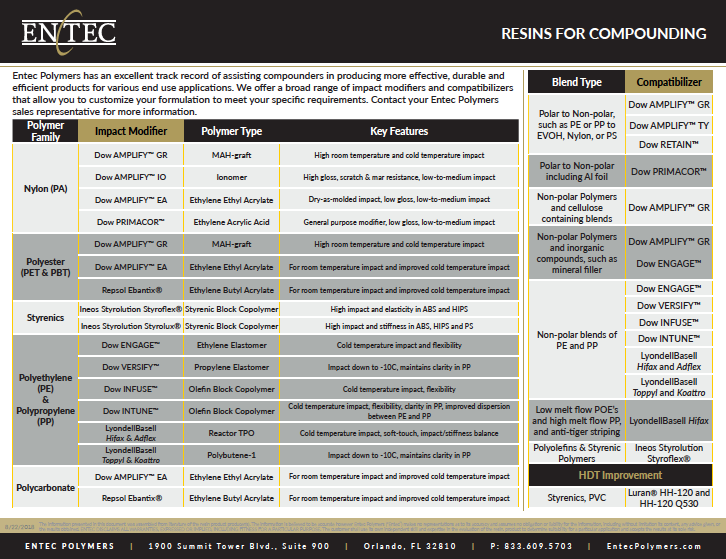

Entec Polymers has an excellent track record of assisting compounders in producing more effective, durable and efficient products for various end use applications.

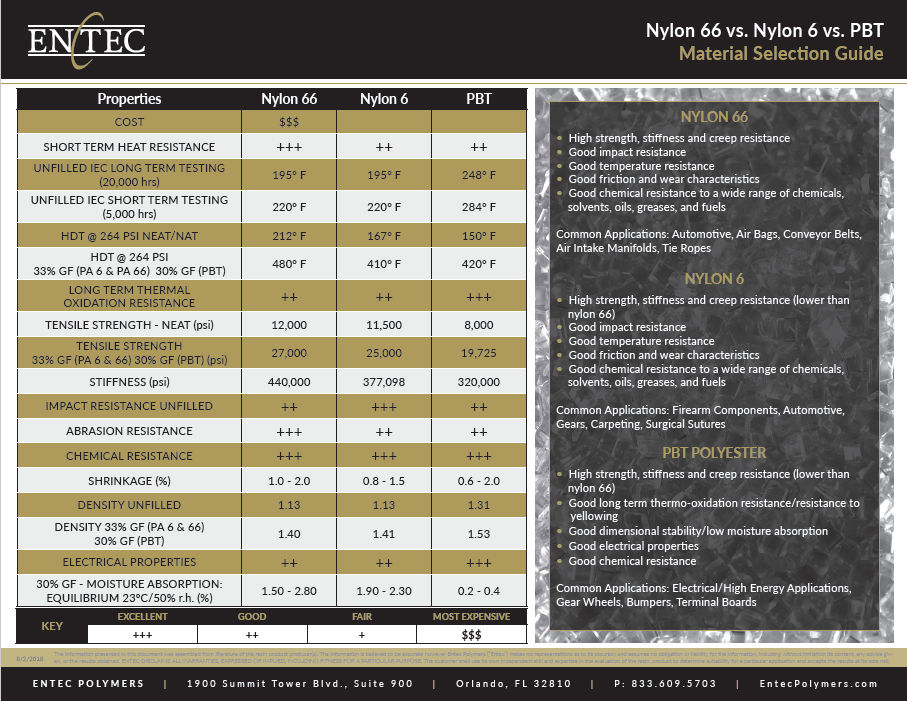

A comparison of these high performance materials that can be used to choose between temperature resistance, strength, moisture absorption and more.

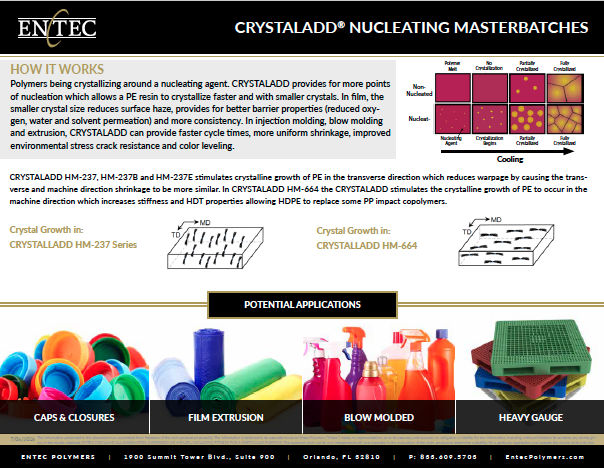

Nucleation technology has been used with polymers such as polypropylene and nylon for many years, and it is an effective aid in helping the polymers to crystallize faster and more consistently and to improve physical or mechanical properties.

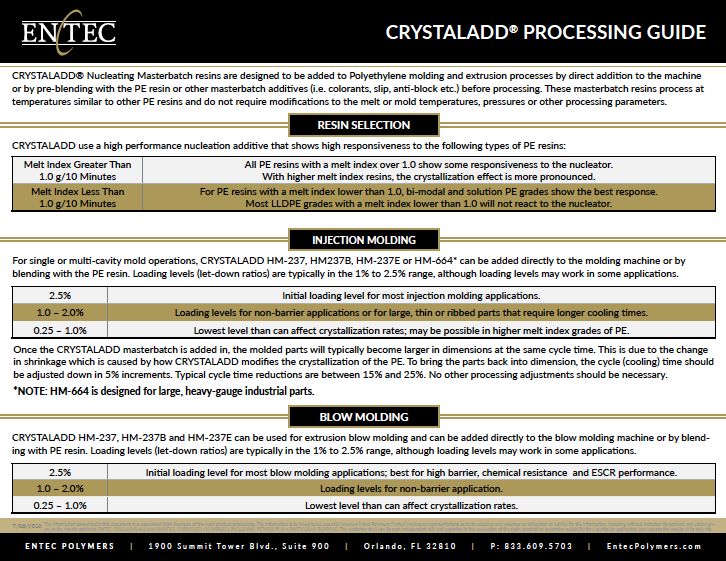

CRYSTALADD® Nucleating Masterbatch resins are designed to be added to Polyethylene molding and extrusion processes by direct addition to the machine or by pre-blending with the PE resin or other masterbatch additives (i.e. colorants, slip, anti-block etc.) before processing.

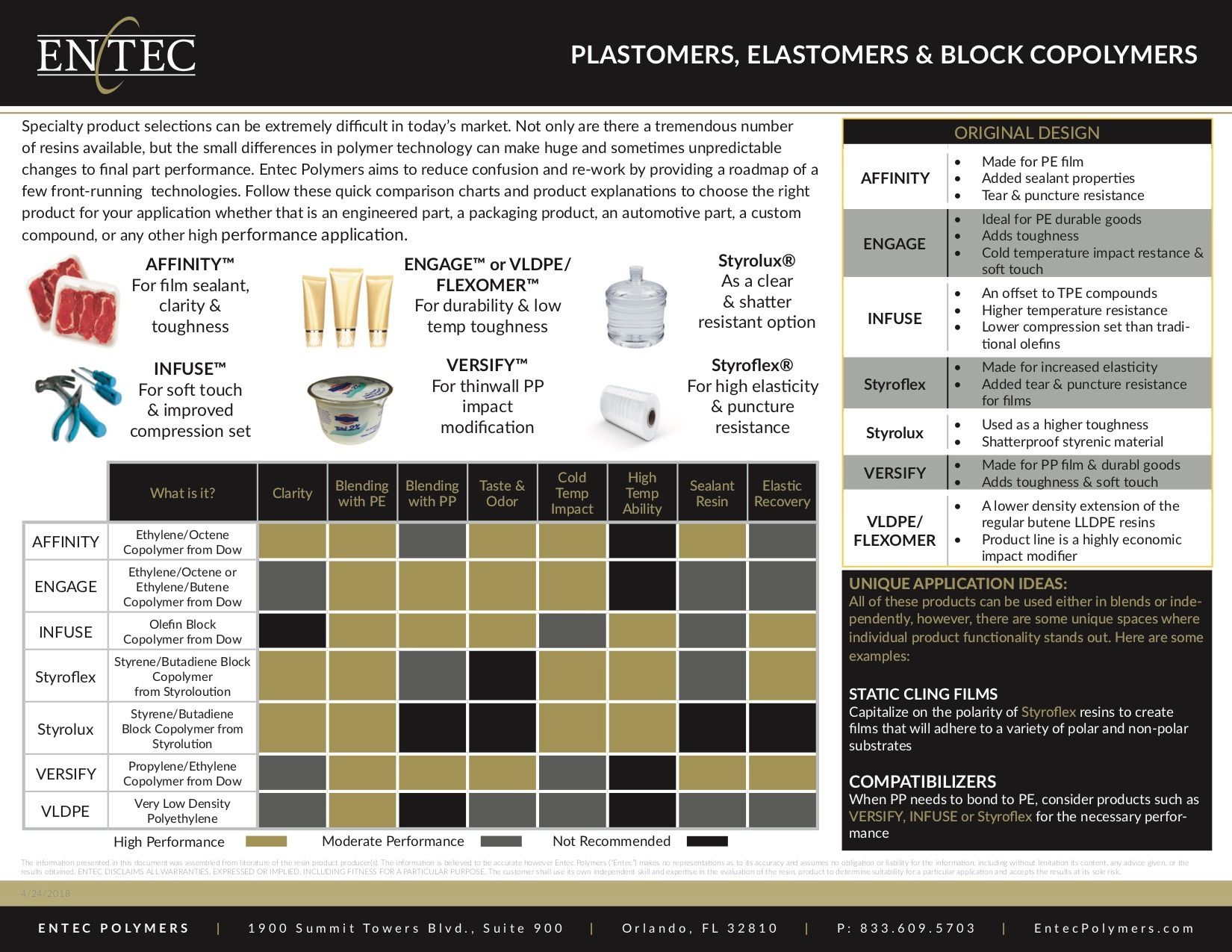

Follow these quick comparison charts and product explanations to choose the right product for your application, whether that is an engineered part, a packaging product, an automotive part, a custom compound, or any other high performance application.

Entec Polymers offers a number of polymers that can be used as modifiers in PVC compounds, with ABS, ASA, SMA, EBA and TPU being the primary ones used.

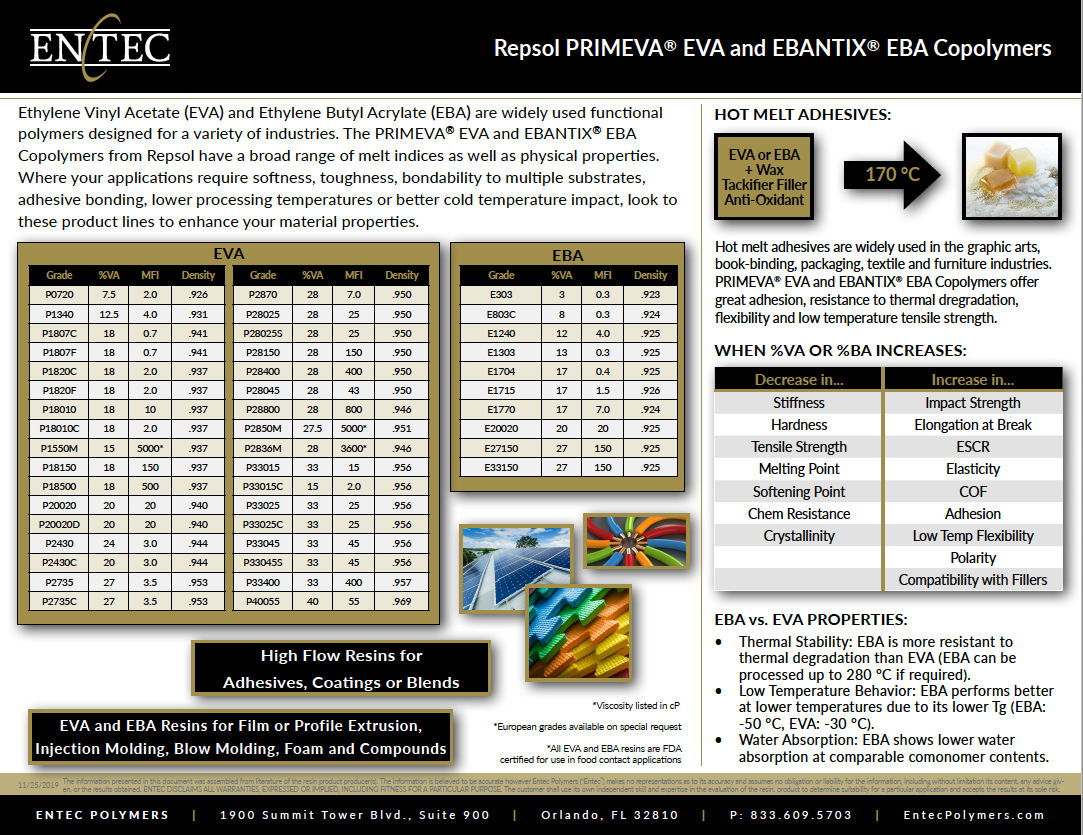

The PRIMEVA® EVA and EBANTIX® EBA Copolymers from Repsol have a broad range of melt indices as well as physical properties.

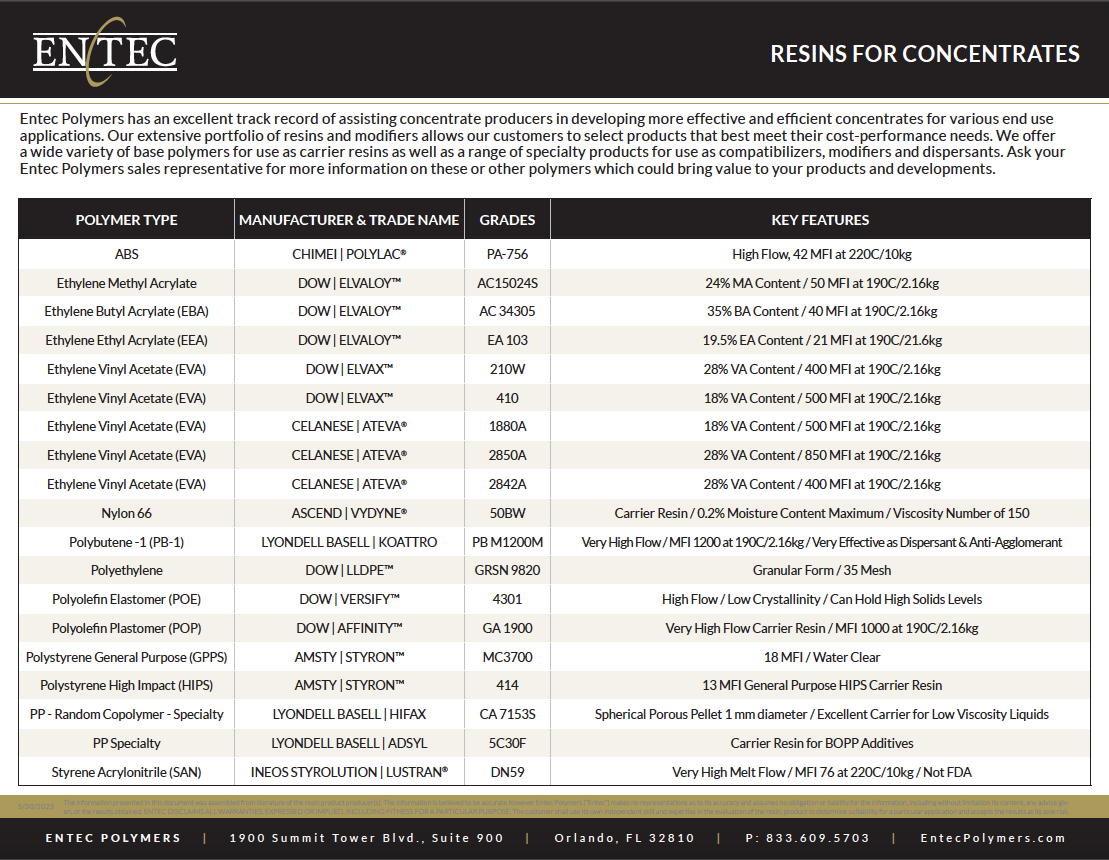

Entec Polymers has an excellent track record of assisting concentrate producers in developing more effective and efficient concentrates for various end use applications.

Automotive polymer materials are used for interior and exterior parts like dashboards, wheel covers, and motor housings.

Commercial / Industrial and Medical Materials