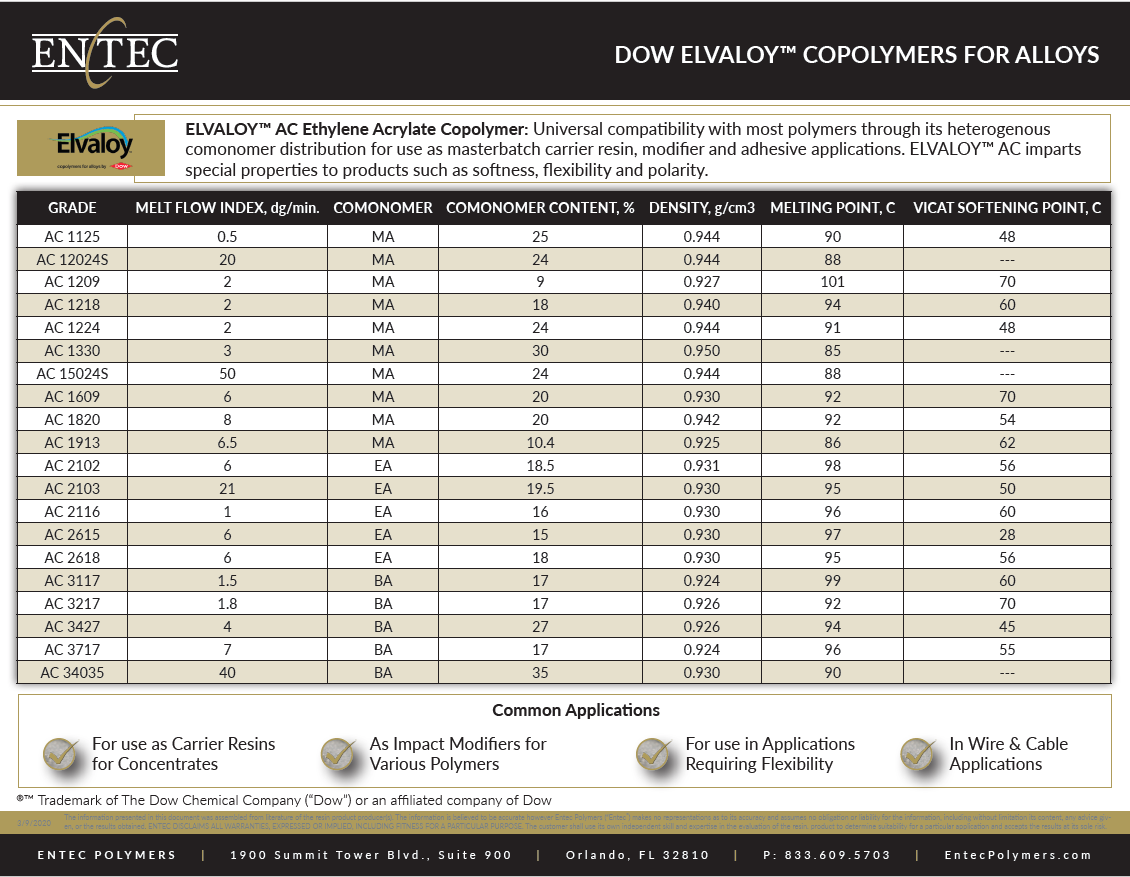

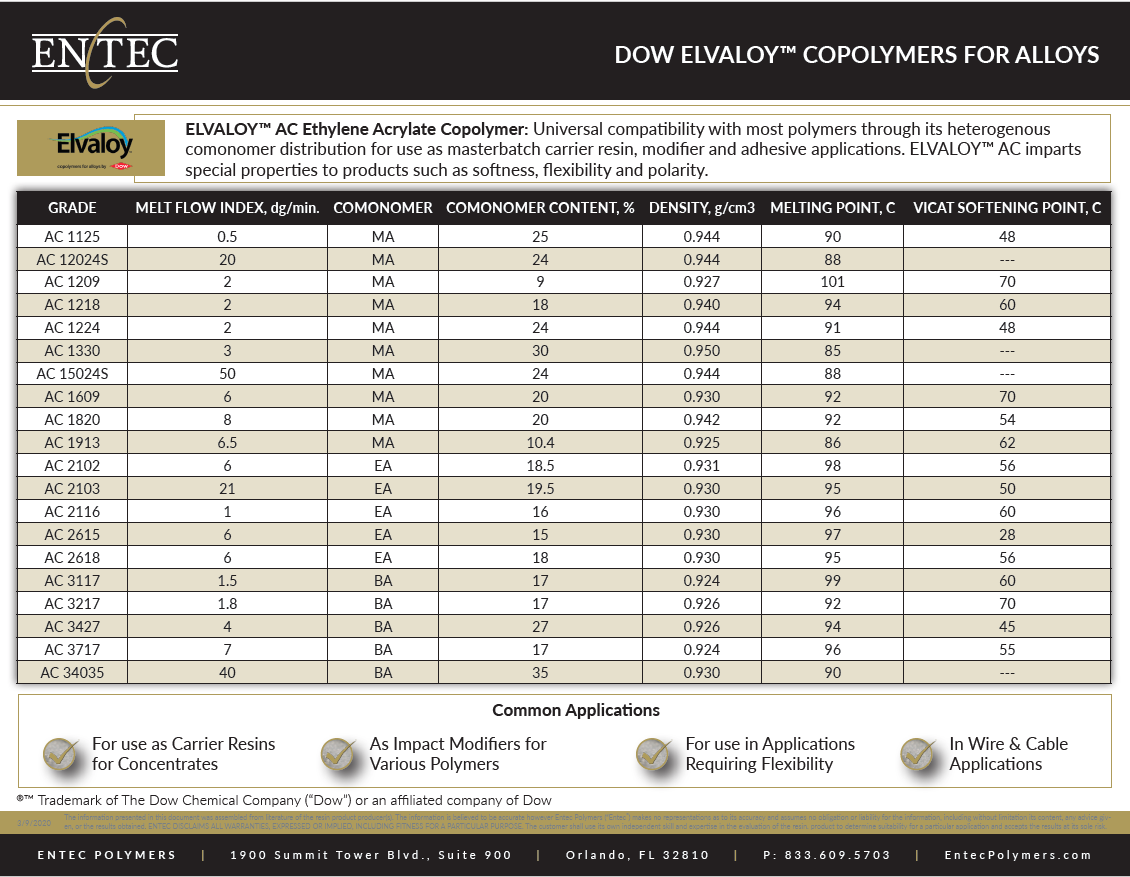

Dow ELVALOY™ Copolymers for Alloys

Need to modify your resin? Improve the compatibility? ELVALOY™ can help!

Learn more about our new customer portal

Customer PortalThe latest research and insights on leading developments in the plastics industry. Find product explanations, properties, comparison charts and application ideas all at a glance.

Need to modify your resin? Improve the compatibility? ELVALOY™ can help!

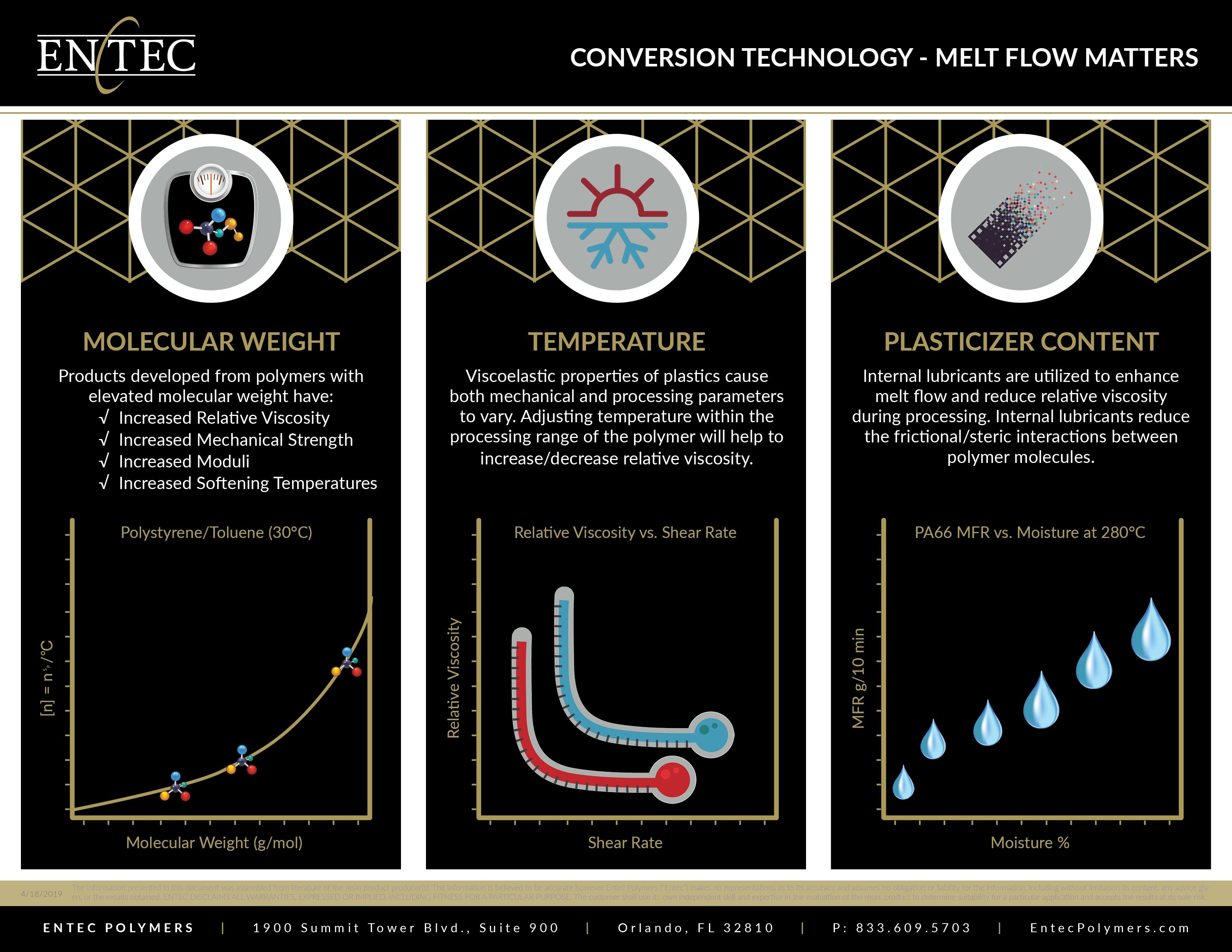

The effects that varying molecular structures play on the rheological properties of various polymer families. The molecular architecture of each unique polymer structure ultimately determines which processes they are best suited to.

Stress whitening got you down? Let us help you eliminate it.

Need a quick lesson on impact testing? See our short overview on impact testing of plastics. Charpy | Izod | Multi-Axial

Celanese Ateva® EVA copolymers are used in many applications including flexible packaging, thermal-lamination film, photovoltaic cells, concentrates and hot-melt adhesives.

Entec is excited to announce the addition of four Dow specialty product families to our broad polymer portfolio. These specialty resins include BYNEL™ adhesive resins, APPEEL™ peelable sealant resins, DOW™ 20 Series ultra-pure polyethylene and CONPOL™ specialty masterbatches.

Is your rubber compound not quite performing? Let Entec Polymers help you with our broad range of modifiers that can be used in rubber compounds.

From molecular structure to mechanical properties: understanding how atomic structure influences material properties and part selection. As a follow up to our series on Crystallinity vs Material Properties, we investigate the influence that chemical structure has on final part performance including melting point, glass transition temperature, barrier properties, ESCR, and UV stability.

Learn More About the Recycling Process Now!

If you want to understand how plastics really affect the environment, then you want to read this article.

The goal of understanding the relationship of shear rate and viscosity of a material is to increase the understanding of how a material process and flow once molten.

The goal of this resin information sheet is to better educate designers and manufacturers and provide them with the necessary information to enable them to choose the correct resin for their roto-molded products and applications.

Determination of crystallinity and general overview of the effects that crystal structure has on the physical properties of polymers.

Having problems with achieving good adhesion in your over-molding application? Let Entec Polymers help with their proven suggestions for achieving maximum adhesion of the over-mold material onto the substrate material.

There has been a lot of recent publicity related to plastic waste in the environment, especially plastic waste in the ocean. Learn more about the facts of plastic recycling.

Do you have a common application? A unique application? An interesting application? Entec Polymers can assist in helping you to select the right polymer to fit your application requirements regardless of how simple or complicated your needs may be.

Wire and Cable Compounds for Different Polymers

While injection molding is common inside the plastics industry, it is important to understand how to troubleshoot issues included with the job. Entec Polymers can assist with your processing needs to create an efficient work environment.

With recent publicity related to recycling plastic, it is important to understand which modifiers can be involved in different plastics. Entec polymers can offer information to help understand how they can affect recycled plastics.

Are you looking to electroplate an injection molded thermoplastic? Entec Polymers offers many different thermoplastics that are capable of being electroplated, along with valuable information to complete the process correctly.

This document highlights some of these more unique and interesting uses of thermoplastic resins. Entec Polymers has the knowledge and experience and is uniquely positioned to assist you with your most unique and challenging uses of thermoplastics resins. Let us help you deliver the solutions to your customer’s most challenging needs!

Regardless of the type of impact modifier or the polymer type it is being utilized in, there is one common factor: the reduction in the melt flow of the final compound.

Introduction to Polymer Compounding. Compounding is a melt blending process where a thermoplastic resin is combined with additives and reinforcements such as anti-oxidants, UV stabilizers, impact modifiers, colorants, flame retardants, glass fibers or minerals. The uses of thermoplastic compounds is only limited by our imaginations and our creativity in developing compounds to meet the end-use requirements.

The purpose of this document is to provide guidance and suggestions for processors that may be unfamiliar with processing post-industrial recycled plastic compounds, such as Entec Polymers ECHO® recycled polypropylene.

First steps when selecting a product for a new application

First steps when selecting a product for a new application.

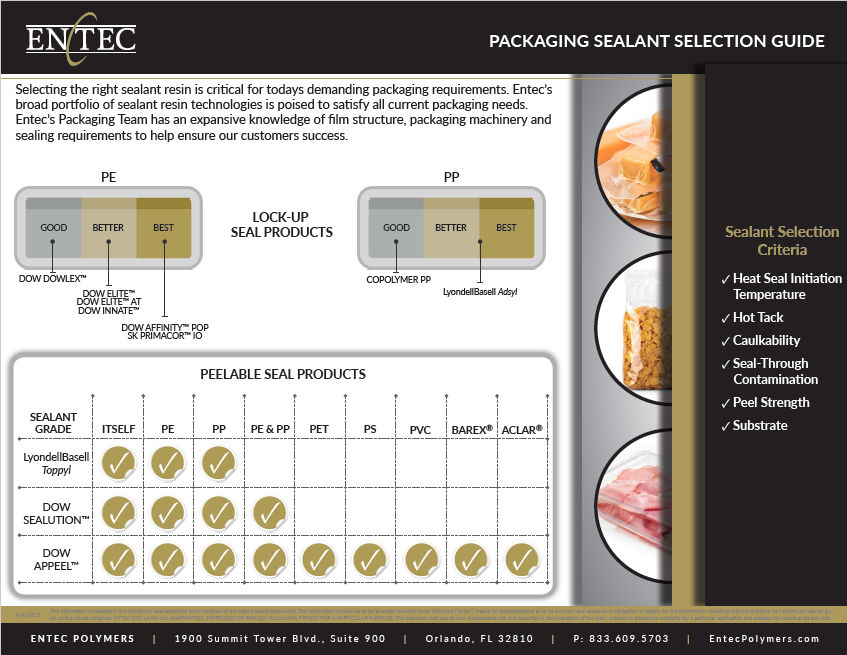

Entec’s broad portfolio of sealant resin technologies is poised to satisfy all current packaging needs. Entec’s Packaging Team has an expansive knowledge of film structure, packaging machinery and sealing requirements to help ensure our customers success.

Formosa Plastics offer a broad range of Formolene reactor compounding Homopolymer and Copolymer resins that offer optimized polymer structures.

Processing issues and defects organized by causes and solutions. Contact our technical team for engineering and processing support.

Two Shot Technology with PP/ASA/Nylon & TPV. Entec offers a cost-effective solution to challenges caused by parts that require the use of two different plastics. Two Shot injection molding is a process that molds one part using two different plastic resins. This enabling technology allows you to integrate two different plastic resins into one part without any post-molding assembly.