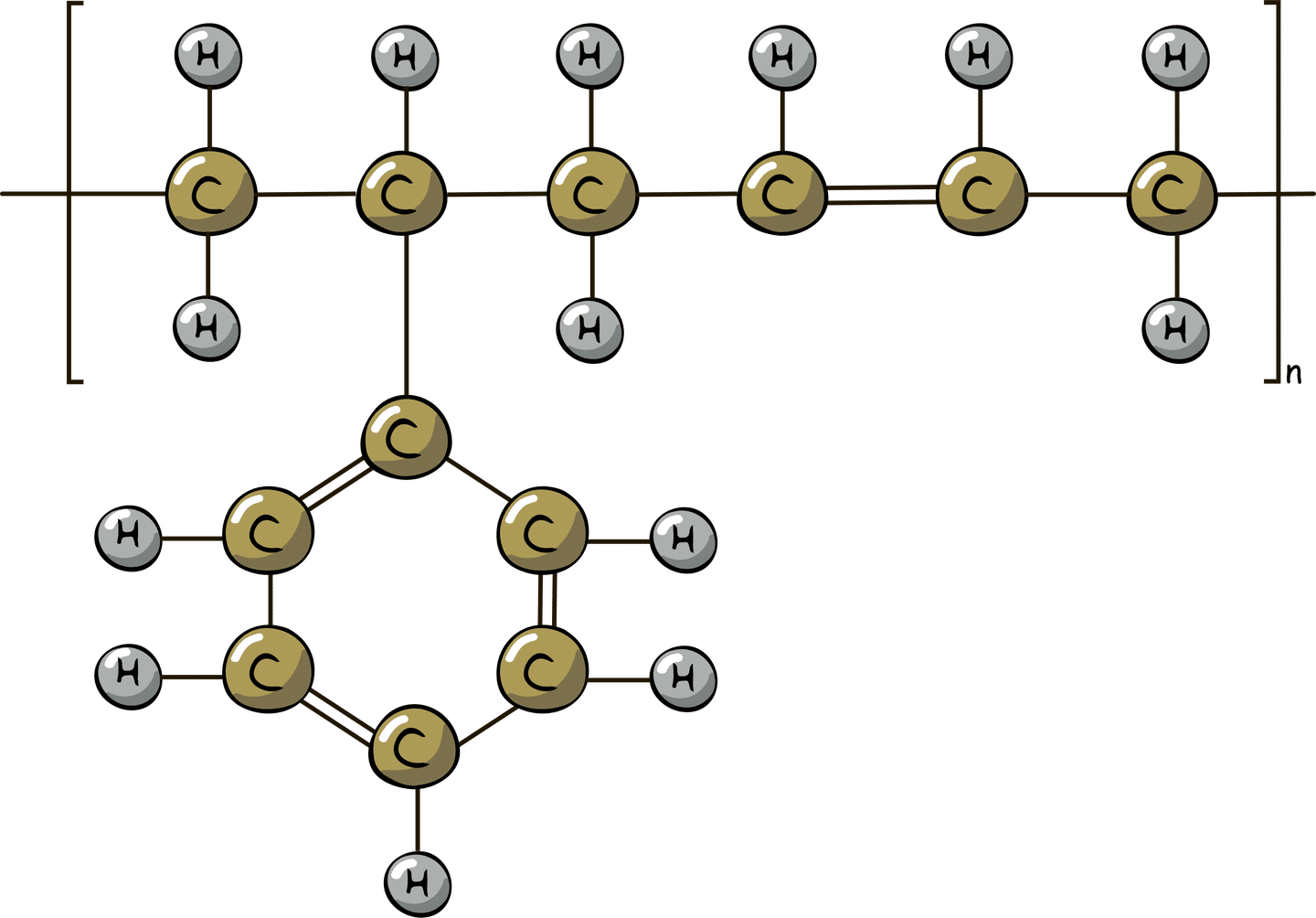

High impact polystyrene (HIPS) is produced by incorporating butadiene rubber into polystyrene to improve its toughness and impact, however this causes the material to become opaque. HIPS offers many similar properties as GPPS, but with higher impact performance and improved resistance to environmental stress cracking. HIPS offers good processability by injection molding, extrusion and thermoforming and is used in applications such as toys, small handheld appliances, appliance parts, vacuum cleaners, packaging containers, and furniture parts.

ABOUT

Polymer Characteristics

- Translucent White in color

- Impact Resistant

- Underwriters Laboratory 94HB

- FDA Compliant

- Good Gloss

- Excellent Aesthetics

- Recyclable

- East to Process Easy to Pain & Bond Good Dimensional stability

Processing Methods

- Injection Molding

- Extrusion

- Blow Molding

- Thermoforming

Typical Applications

- Medical Devices

- Packaging

- Toys