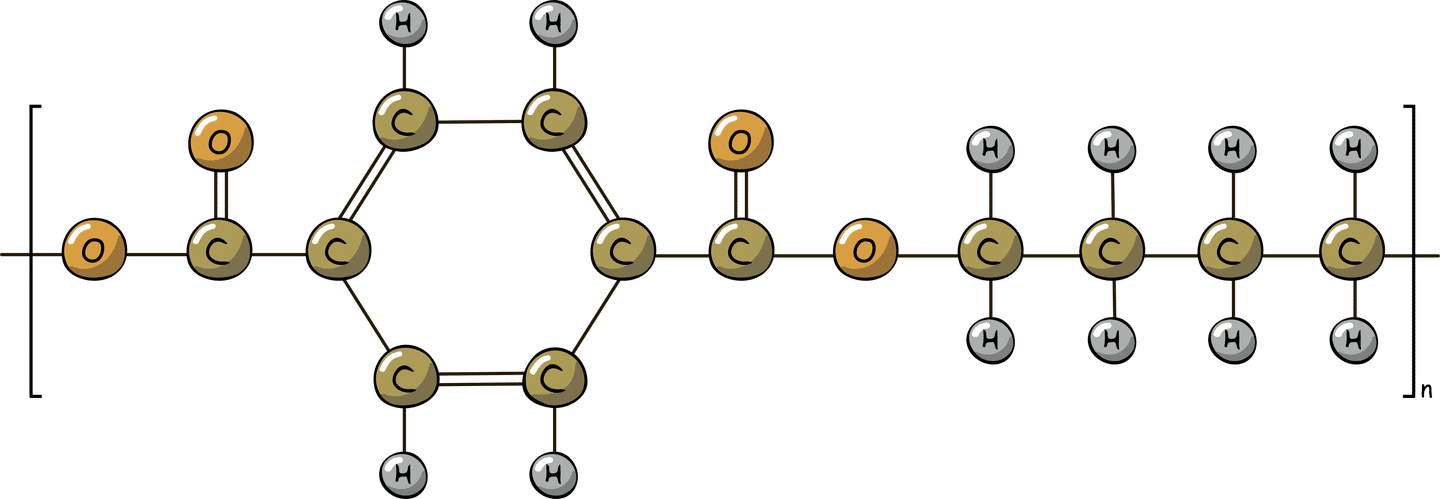

Polybutylene Terephthalate (PBT) is a semi-crystalline polyester produced by the reaction of terephthalic acid or dimethyl terephthalate with 1,4-butaindiol using special catalysts. Key properties of PBT include high strength and stiffness, dimensional stability, low water absorption, good chemical resistance, good oxidation (yellowing) resistance, and excellent electrical properties. PBT is processed by most standard processing techniques including injection molding, blow molding, and extrusion.

Typical applications for PBT include windshield wiper arms, door handles. connectors, electrical housings, automotive mirror housing supports, circuit breakers, electric switches, fibers, window profiles, toys and film.

ABOUT

Polymer Characteristics

- Good strength and stiffness

- Good temperature resistance

- Good chemical resistance

- Good tribological properties

- Low moisture absorption

- Low oxidative yellowing

- Excellent electrical properties

- Rapid crystallization and fast cycle time

Grades

- Glass fiber and glass sphere reinforced

- Glass fiber reinforced with very high surface gloss

- Glass fiber/mineral reinforced

- Flame retardant

- UV stabilized

- Hydrolysis resistant grades

- Medical

- Special colors for laser marking

Processing Methods

- Injection molding

- Extrusion

- Meltblown

- Water- and gas-injection technology

Typical Applications

- Housings

- Connectors

- Electrical components (arc suppressors, switch bases)

- Door handles, windshield wiper arms