Nylon 6 vs 66

Discover the nylon showdown: Nylon 6 vs. Nylon 6/6! Uncover their shared strengths, contrasting structures, and find out where each reigns supreme in industries like automotive, fashion, and beyond.

Learn more about our new customer portal

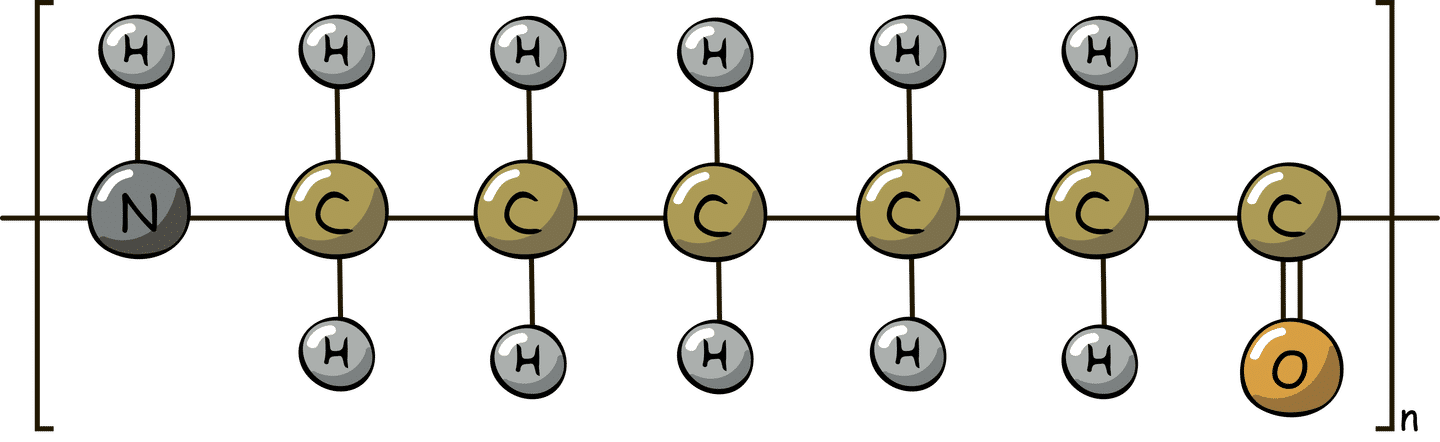

Customer PortalPolyamide 6 (PA6, Nylon 6) is produced by the ring opening polymerization of caprolactam. Nylon 6 is a semi-crystalline engineering resin that offers a good balance of mechanical and thermal properties, impact resistance, chemical resistance, and low friction and wear. Nylon 6 is processed by all common processing methods.

Typical applications for Nylon 6 include interior, exterior and under-hood automotive components, electrical and electronic components, connectors, office furniture, cutlery and cooking utensils, lawn and garden tools, fiber and filaments, and film.

Nylon 66 has these advantages over Nylon 6:

Nylon 6 has these advantages over Nylon 66:

In many applications, Nylon 6 and Nylon 66 can be interchangeable.