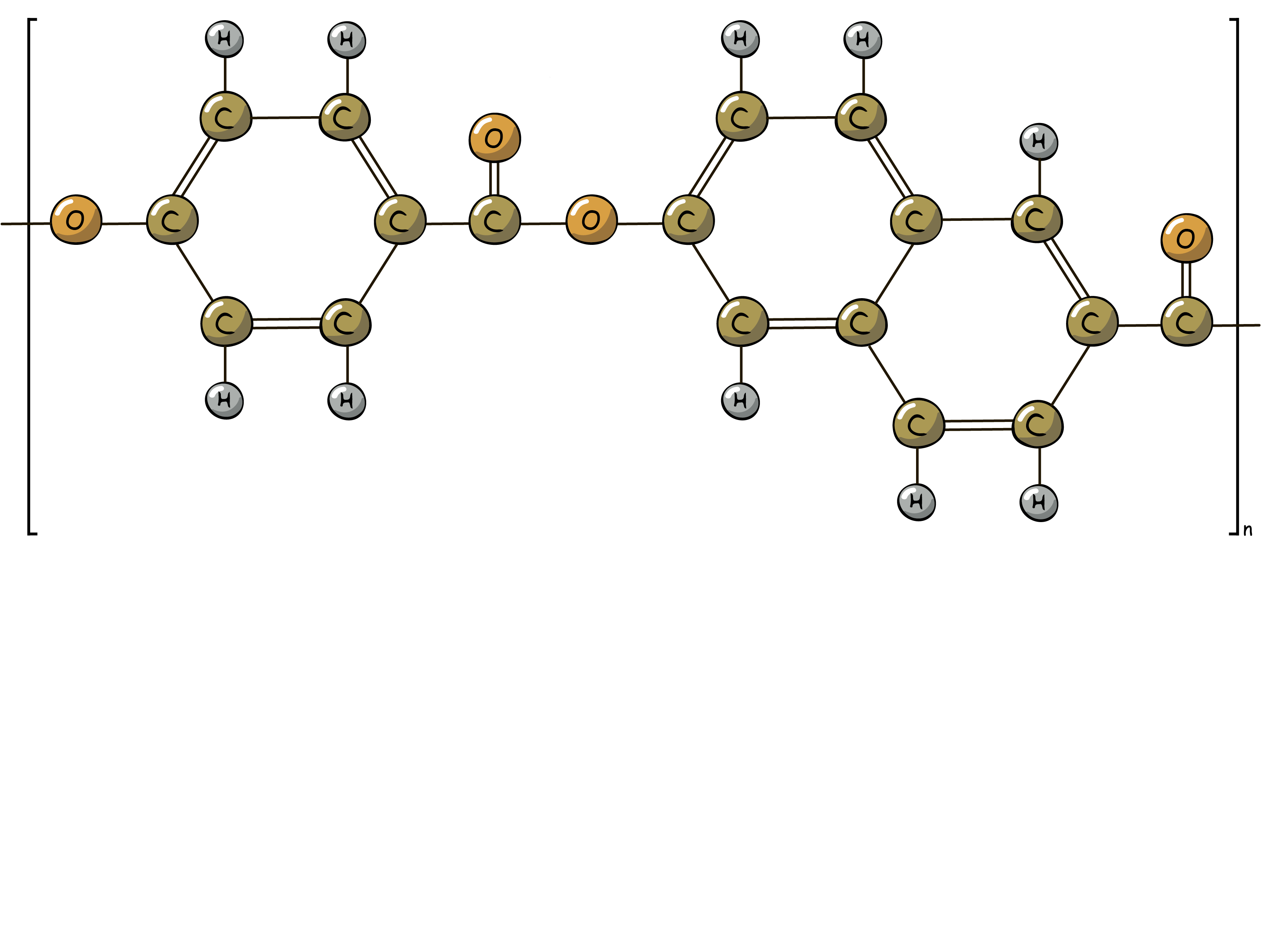

Liquid crystal polymers (LCP) are high performance polymers that feature a unique molecular structure that consists of rigid, rod-like macromolecules. When the LCP is subjected to shear during processing, the rigid molecules order themselves into fibers and fibrils which are frozen-in when the polymer cools. This is why LCP's are considered as self-reinforcing polymers. Key characteristics of LCP's are very high continuous use temperatures, inherent flame retardancy, excellent oxidation and chemical resistance, very high strength and stiffness, low coefficient of thermal expansion, and very low melt viscosity. Applications for LCP's include electric and electronic components, connectors, cookware, film, medical equipment, fibers, rope, sporting goods, and automotive and aerospace components.

ABOUT

Polymer Characteristics

- High strength and stiffness

- High HDT (270°C / 518°F)

- Long term CUT 220°C / 428°F

- Excellent chemical resistance

- Very high melt flow

- Inherently self-extinguishing (UL 94 V0)

- Halogen free

- Dimensionally stable (to tolerance class T6)

- Very low coefficient of thermal expansion

Grades

- Glass fiber reinforced

- Carbon fiber reinforced

- Fiber/filler modified

- Medical technology

- Electro-plating

- Conductive

Processing Methods

- Injection molding

- Extrusion

- Co-extrusion

- Thermoforming

Typical Applications

- Connectors, bobbins, sockets, switches, chip carriers

- Components for surface mount devices

- Pumps, impellers, meters

- Sterilizable trays, dental tools, surgical instruments

- Components in printers, copiers