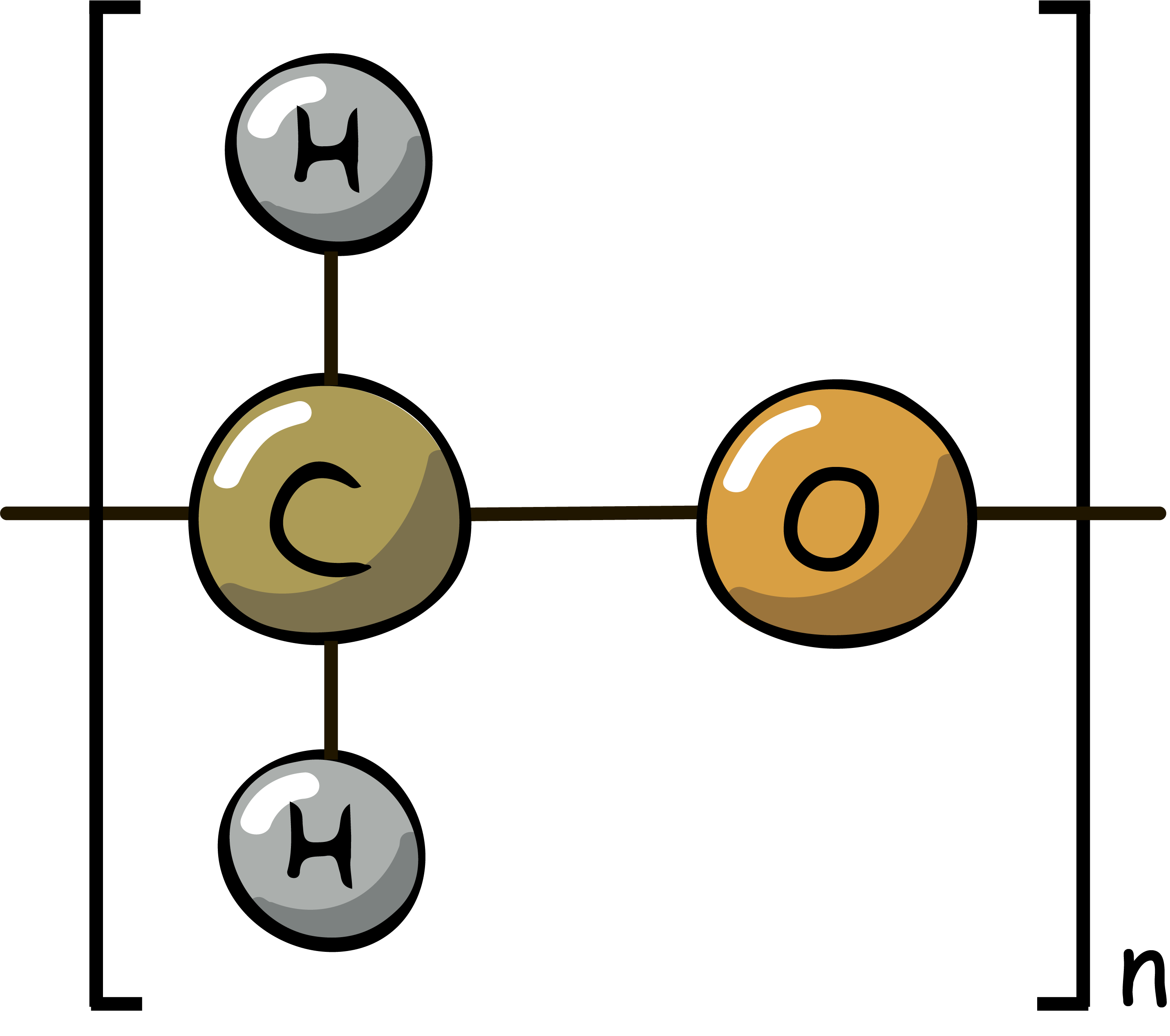

Polyoxymethylene, or acetal, is an engineering thermoplastic produced by the reaction if trioxane and a second comonomer. Acetal resins are known for their outstanding balance of properties, offering high stiffness, high mechanical strength, good dimensional stability, high fatigue strength, good creep resistance, good friction and wear characteristics, good chemical resistance and easy processability. Acetal is available in a wide range of product types including unfilled, glass reinforced, mineral reinforced, impact modified, low wear, anti-static, and UV resistant. Acetal polymers are commonly used in engineering applications such as gears, washers, clips, conveyor links, drapery components as well as irrigation and plumbing components.

ABOUT

Polymer Characteristics

- Good strength and stiffness

- Good toughness (to -40°C)

- Excellent chemical resistance

- Good tribological properties

- Good resiliency and fatigue

- Low moisture absorption

- Good dimensional stability

- Good hydrolysis resistance (copolymers)

Grades

- Glass fiber and glass sphere reinforced

- Improved low friction and wear-resistant property

- High impact

- Medical technology

- Low odor emission

- Hot diesel-resistant

- UV stabilized

- Electrically conductive

Processing Methods

- Injection molding

- Extrusion

- Rotational molding

- Physical foaming

- Gas and water-injection technology

Typical Applications

- Gears, bearings, bushings

- Plumbing components

- Seat belt, door handles, door lock components

- Automotive fuel caps and fuel system components

- Pump impellers